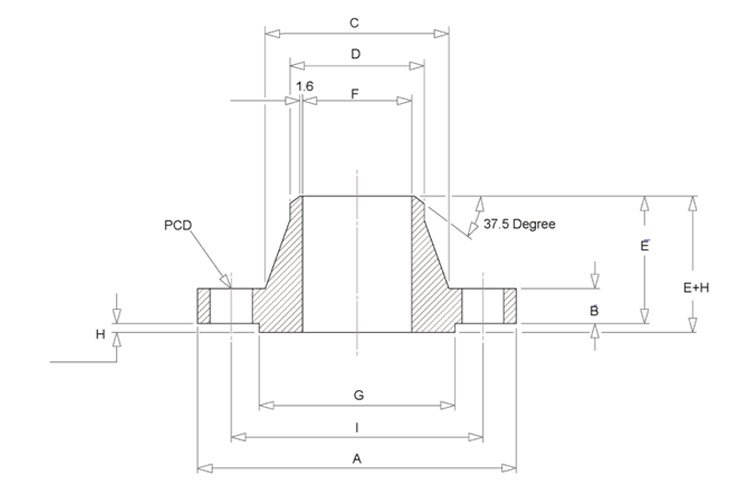

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Welding Neck bore is derived from the pipe schedule | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Applications of Weld Neck Flange Class 150

Weld Neck Flanges Class 150 are widely used in industries where strength, safety, and leak-proof connections are required. Moreover, they are preferred in piping systems that handle low to medium pressures.

- Oil & Gas Industry: These flanges are applied in crude oil, natural gas, and petroleum pipelines. As a result, they ensure long-lasting and reliable operations.

- Petrochemical Plants: They are suitable for process piping where resistance to pressure and temperature fluctuations is needed. Furthermore, their smooth bore minimizes pressure drop.

- Power Plants: Weld neck flanges are used in cooling water lines, steam pipelines, and boiler connections. Consequently, they enhance efficiency and reduce maintenance.

- Water Treatment Plants: They are commonly installed in desalination systems, wastewater treatment units, and water supply lines. In addition, their corrosion-resistant materials ensure durability.

- Chemical Industry: Since many chemicals are corrosive, weld neck flanges provide a secure and reliable joint. Therefore, they are essential in chemical transfer systems.

- Food & Beverage Industry: Stainless steel weld neck flanges are utilized in sanitary and hygienic pipelines. Similarly, the pharmaceutical industry adopts them to maintain contamination-free processes.

- HVAC Systems: They are used in chilled water, condenser, and cooling tower pipelines. Moreover, they provide a strong connection that withstands thermal cycling.

- Marine & Shipbuilding: Weld neck flanges Class 150 are suitable for seawater and general marine pipelines. Thus, they contribute to long-lasting ship systems.