JSK Engitech Industries – Precision. Performance. Perfection.

JSK Engitech Industries is a trusted manufacturer and supplier of high-quality Hydraulic Fittings, Flanges, and Valves, serving a wide range of industries across India and abroad. With years of engineering experience and a strong commitment to excellence, we have built a solid reputation for delivering reliable, durable, and precision-engineered products that meet global standards.

We specialize in the design and manufacturing of:

- Hydraulic Fittings

- Weld Neck Flanges

- Blind Flanges

- Ball Valves

- Needle Valves

- Y Strainers

- Butterfly Valves

- Brass Fittings

- All Types of Flanges and Valves

Our Vision and Mission

To become a leading global brand in the field of fluid control and industrial fittings by providing innovative, high-quality, and cost-effective engineering solutions that contribute to the efficiency and safety of industrial operations worldwide.

Our Missions are manufacture and supply precision-engineered fittings and valves that meet or exceed international quality standards. To continuously innovate and upgrade our technology to serve diverse industries more efficiently. To build long-term partnerships with our customers based on trust, integrity, and customer satisfaction. To ensure timely delivery and provide customized solutions as per client specifications.

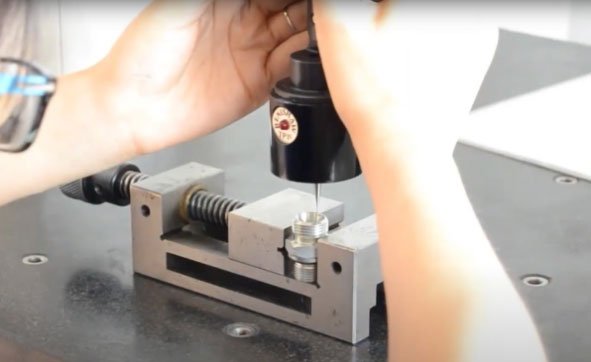

Infrastructure & Manufacturing Facility

Our state-of-the-art manufacturing unit is equipped with modern CNC machines, lathes, testing instruments, and fabrication tools, enabling us to produce fittings and valves that match international standards like ANSI, ASME, DIN, and BS.

We have a team of experienced engineers, skilled technicians, and quality experts who ensure every product leaving our facility reflects our commitment to engineering excellence.

Quality Assurance

Quality is at the core of JSK Engitech Industries. From raw material selection to final inspection, every step of our manufacturing process follows stringent quality control procedures. Our products are designed and tested to withstand high pressure, temperature variations, and demanding industrial environments.

We use premium-grade Stainless Steel, Carbon Steel, Alloy Steel, and Brass materials, ensuring superior corrosion resistance, mechanical strength, and longevity. Each component is thoroughly checked for dimensional accuracy, surface finish, and performance before dispatch.